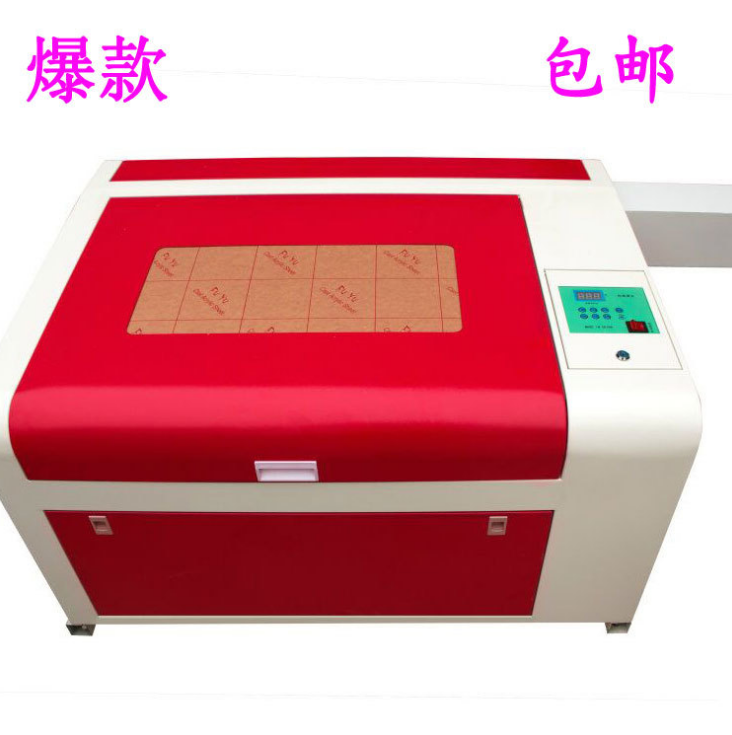

Лазерный станок - гравер Walter Fernandez WD-4060 (103-112)

Есть в наличии

Есть в наличии

Лазерный станок - гравер Walter Fernandez WD-4060. Низкая цена, высокое качество.

Аксессуары станка WD-4060

- USB-порт провода

- Линия электропередачи

- Руководство пользователя

- Компакт-диск программного обеспечения

- Ключ USB

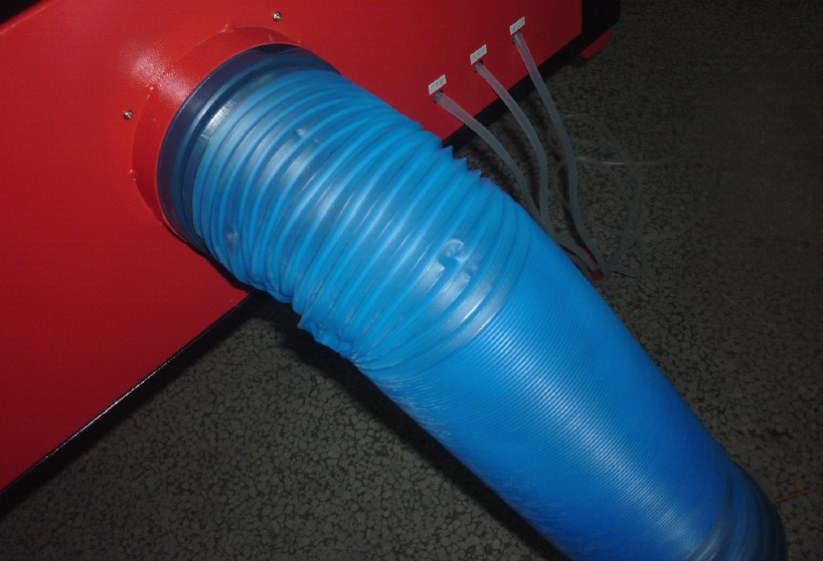

- Дымовая труба

- Водяной насос

- Воздушный насос

|

Модель |

WD-4060 |

|

Производитель |

Walter Fernandez |

|

Мощность лазера |

50Вт, 60Bт, 80Вт, 100Bт |

|

Длина волны лазера |

1064 (nm) |

|

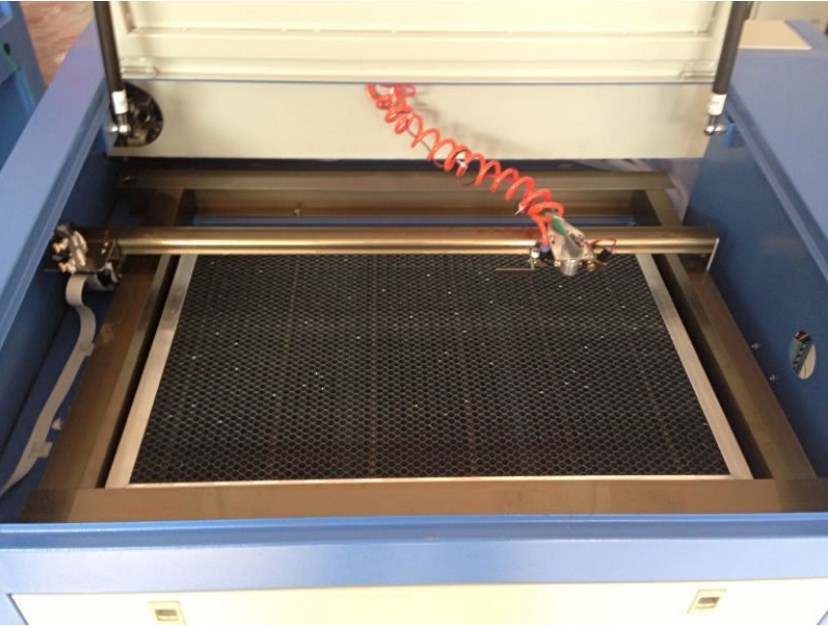

Рабочая зона |

400 * 600 (мм) |

|

Рабочая глубина |

≤0.01мм (на основе материала) |

|

Максимальная глубина |

0-10 (мм) |

|

Рабочая скорость |

0-3600 (мм/с) |

|

Ускорение |

0-30000 (мм/мин) |

|

Максимальная скорость линии |

950 (мм/с) |

|

Точность позиционирования |

0,1 (мм) |

|

Охлаждение |

Воздушное / водяное охлаждение |

|

Режим контроля |

Автоматический |

|

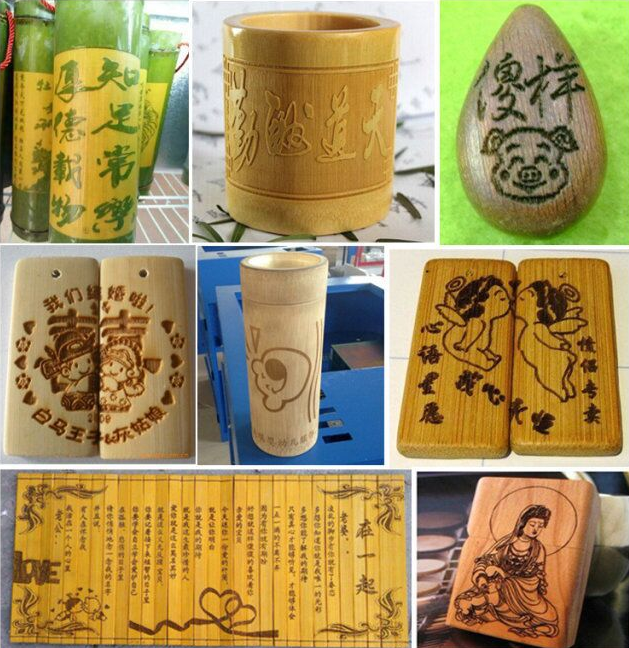

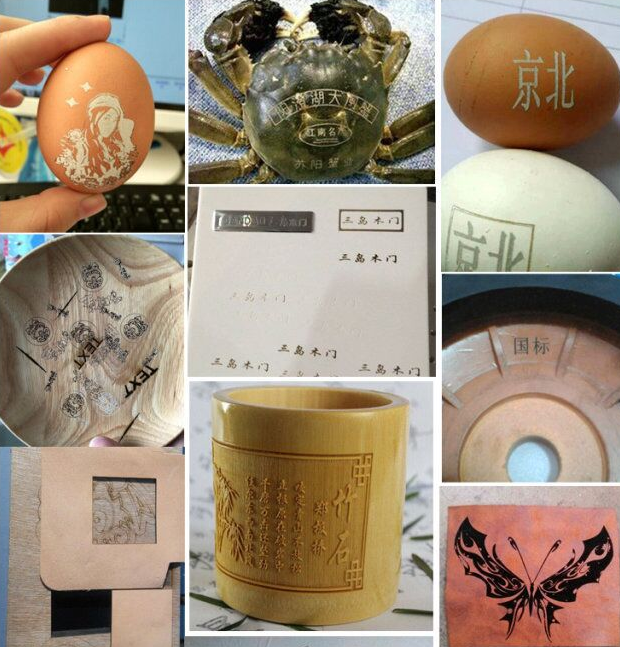

Предназначение |

Фармацевтика, подарки, изделия ручной работы, юверирные изделия, продукты питания, оборудование, машины, игрушки и т.д. |

|

Применение |

Металл / Пластик / Дерево |

|

Диапазон обработки |

110 (мм) |

|

Входная мощность |

220V / 50HZ / 60HZ |

|

Рабочая температура |

0-45 (℃) |

|

Потребляемая мощность |

450 (Вт) |

|

Размеры (ДxШxВ) |

1020 * 750 * 580 (см) |

|

Вес |

90 (Кг) |

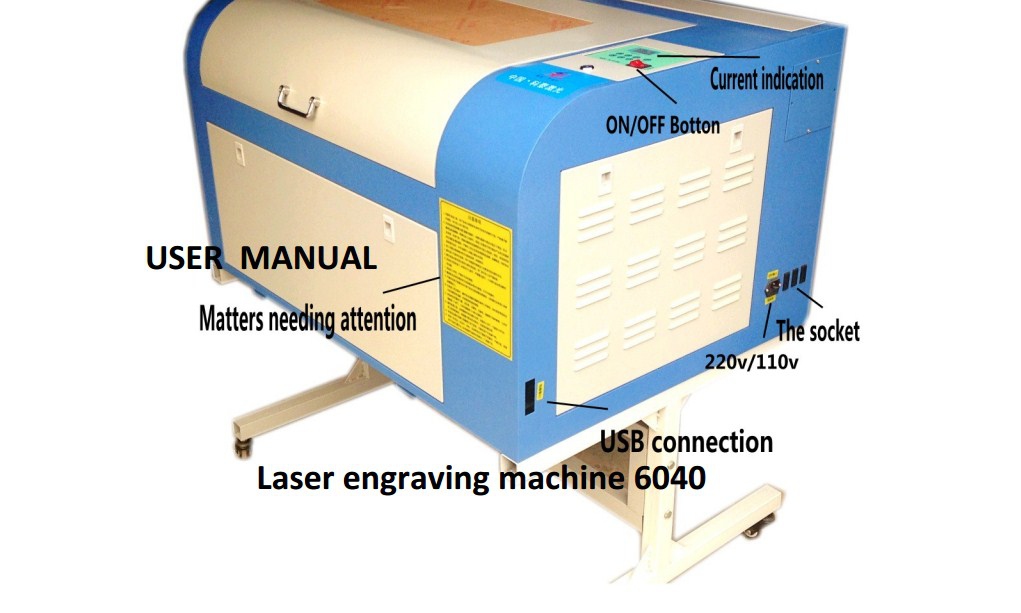

The machine accessories

- Usb port wire

- power line

- user manual

- The software CD

- The USB key

- smoke pipe

- water pump

- Air pump

Installation instructions

1. After receiving the machine, open the packing cases, open the host machine, accessories, and cut off the machine platform above the belt

2. Connect the power cord, USB cable and the host is good

3. Connect water pump (machine with clear water and water)

4. Good connection after put the pump into the bucket, outlet pipe into the above the water, can see the water situation

5. Tracheal card to the rear of the machine, and then fan above have crack, it is best to tape sealing

6. The machine cable and USB key (that is, with little U disk) into the host computer or laptop U mouth

7. Connect the USB cable and the machine

Operating instructions :

1. Engraving procedures: Turn on switchboard of the engraver and make sure cooling water circulation is functional. After measuring the engraving object.

Pinch it on the focus of the focus lens . Turn on computer, enter engrave surface and make typesetting.

2. Notes and maintenance points :

a) The engraver should be put on flat surface without slant. Avoid collision when move.

b) Check out cooling water, pararrel line and switch before getting in use.

Conduct without cooling water is strictly prohibited to proof against laser destruction. Reflection mirror and focus lens should be examined frequently with absorbent cotton wiping off the dirt. Damaged plating coat should be replaced in time.

c) Deviated light road should be adjusted instantly during engraving process (non-professionals are prohibited to touch it ).

d) Before engraving new material, first judge it whether suitable to the laser engraver and get parameters through experiment. During engraving process, any part of human body is prohibited putting into light road avoid being burnt).

Note: laser .reflection mirror and focus lens are exhaustible material. Ventilation pipe should be connected outdoors.

Common breakdown and the fixation :

A. After typesetting and output .if the laser head don ’t move , you should :

a) Be sure that the engraver is connecting to the computer.

b) Shut off the switch and check whether the parallel line is well connected.

B. If the laser don’t illuminate , you should :

a) Be sure that the laser switch has been pressed down.

b) Check whether the electric current button at the zero place. If so, adjust it to appropriate place.

c) Observe the cooling water in normal process or not. If it stops to work, maybe the laser has been damaged, and you should shut off the machine immediately.

In half an hour, check whether the cooling water unit returns to normal state, if so reopen the machine.

d) If the power of the laser decreases, then maybe it reaches its longevity and should replace it in time. If the laser work normally and engraving parameter is right. But engraving effects is not good. then you should :

a) Check whether engraving surface is on the focusing area of the focus lens.

b) Judge whether the engraver power is decreasing . If so , you should increase output current or change the laser .

c) Check whether the light road is diverted: cover the entrance of the first , second and third reflector (the first generation machine has four reflectors) with polyester film successively , press down laser switch and hand checking switch . observe the location of light spot . If the spot diverts from the certer of entrance . you should adjust the position and angle of laser or reflector slightly to guarantee the light road pass through the focus lens . (The adjustment of light road is not easy . please contact the maintenance section.)

d) If extra lines take place in engraving process; you should check the pararrel digital line and replace it if necessary.